Can Graphene Be Used as A Load Bearing Material in Structures?

Graphene Material Use In Structures Dissertation -This report will be mainly focused on the materials used in the construction industry. It is almost impossible to find out the optimal material for a particular structure. Concrete has high compressive strength under compression however, concrete is very weak in tension. This problem can be distant by the addition of steel rebar’s that act as a reinforcement.

Research has indicated that adding short chopped fibres to the cement-based composite can substantially increase the tensile as well as the compressive strength. The fibres used in this report (alkali-resistant glass fibre and carbon fibre) are described as a hair-like material which is visibly seen as a piece of thread. Synthetic fibres, such as polypropylene and nylon, can be replaced by natural fibres (glass fibre and carbon fibre).

This is a more sustainable path since the construction industry will not use high amounts of energy to produce such fibres. As stated above, the material required for this project should be alkali-resistant. This concludes that alkali-resistant glass fibre and carbon fibre are the most suitable types of material by outlining the benefits of using different types of fibres when reinforcing concrete in the construction industry.

Moreover, this project will promote the use of natural fibres in order to enhance sustainable construction without compromising the mechanical properties of the concrete composite members. The project now involves compressive and tensile testing of Carbon Fibre Reinforced Concrete and Alkali-resistant Glass Fibre Reinforced Concrete with two different percentages of fibre content. Eight plain concrete samples were casted for comparison. (four for tension and four for Compression).

Sixteen samples were reinforced with Alkali-resistant Glass fibre at 0.1% and 0.2% (by weight) and sixteen samples were reinforced with Carbon Fibre at 0.1% and 0.2% (by weight). The main reason behind using two different fibre content percentages is to provide an understanding of the effect of fibre content on the tested mechanical properties with minimal errors possible. The mix design proportion was chosen to be 1.5:2.5:3, Cement: Sand: Aggregates (by weight) with water cement ratio 0.5. All the 40 specimens were water cured for 28 days in order to reduce the margin of errors by calculating the average of all four specimens.

- An increase in compressive strength was present when increasing the fibre content from 0.1% Carbon Fibre to 0.2% Carbon Fibre.

- There was negligible increase/decrease in compressive strength when increasing the AR Glass Fibre content from 0.1% to 0.2%.

- An increase in tensile strength was present when increasing the Carbon Fibre content from 0.1% to 0.2%.

- An increase in tensile strength was present when increasing the AR Glass Fibre content from 0.1% to 0.2%.

- 14,000 words – 70 pages in length

- Excellent use of literature

- Excellent analysis of subject area

- Well written throughout

- Ideal for civil engineering students

1 – Introduction

2 – Literature Review

Glass Fibre Reinforced Concrete

Types of Glass Fibre Reinforced Concrete

Strength Properties of Glass Fibre Reinforced Concrete

Properties of Glass Fibre Reinforced Concrete (GFRC) in the fresh state

Properties of Glass Fibre Reinforced Concrete (GFRC) in the hardened state

Applications of Glass Fibre Reinforced Concrete

Glass Fibre Reinforced Concrete at the Presidential Palace Abu Dhabi

Effects of Fibre Volume on Concrete

Other factors affecting Glass Fibre Reinforced Concrete

Carbon Fibre Reinforced Concrete

Properties of Carbon Fibre Chopped Strands

Properties of Freshly Mixed and Hardened Carbon Fibre Reinforced Concrete

Compressive Strength of Carbon Fibre Reinforced Concrete Cylinder

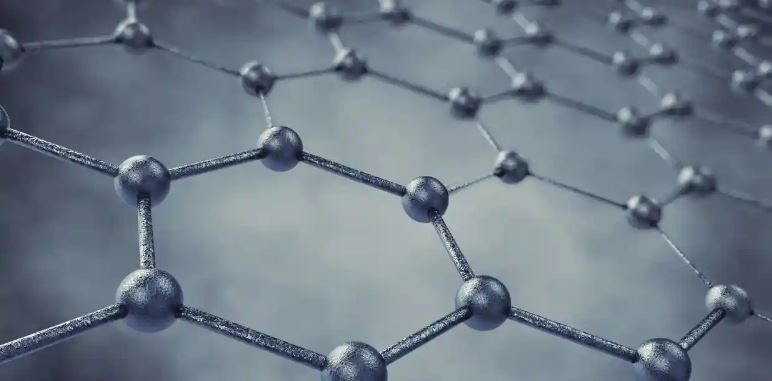

Graphene Reinforced Concrete

What is Graphene?

Properties of Graphene

Testing

Compressive Strength

Split tensile strength

Other Tests that can be conducted for further study

Durability

3 – Health and Safety

4 – Material Selection

5 – Methodology and Materials

Materials

Coarse Aggregate

Fine Aggregates

Cement

Water

Alkali-Resistant Glass Fibre

Carbon Fibre Chopped Strands

Specimen preparation

Concrete Making

Mix Design

Mixing, Casting, Compacting and Curing Concrete

Sulphur Capping Testing

Split Tensile Test

Compressive Strength Test

Errors

Human Errors

Equipment Errors

Expectations

6 – Results and Discussion

Plain Concrete

Carbon Fibre Reinforced Concrete

AR Glass Fibre Reinforced Concrete

Carbon Fibre Reinforced Concrete vs. AR Glass Fibre Reinforced Concrete

7 – Conclusion

Bibliography

Appendix Section